Calibration Services - Maximizing Product Performances

Albertine with its partner Faure Herman can perform both calibration checks and re-calibration of flowmeters over a wide range of flowrates and viscosities.

Calibrations are performed in compliance with International Standards such as OIML, API, ISO and NPD requirements as well as specific requirements from customers. Based on years of experience, periodical product calibration is highly recommended to keep equipment under optimum operating conditions

Our calibration facilities:

- Guarantee optimum verification of meters performance,

- Benefit from a high level of expertise and know-how in metrology,

- Propose calibration over full customers’ application range,

- Secure onsite flowmeter measurement accuracy.

I. FAURE HERMAN CALIBRATION

Major added value of Faure Herman calibration facilities

The objective of the Faure Herman laboratory is to provide our customers a comparable and reliable measurement:

- Calibration is done with Hydrocarbon fluids at real operation conditions: viscosities, flowrates.

- In addition to verification, capability to adjust flow meters in our workshop.

- Traceability fully established to International Standards.

- Independent Calibration Laboratory verified by COFRAC/ILAC (ISO17025) accreditation.

- Worldwide recognized calibration results through the ILAC/MRA (Mutual Recognition Agreements).

- Calibration benches uncertainties meet the most stringent requirements.

State-of-the-art Flow laboratory

Our partner, Faure Herman has 11 calibration stations for testing liquid and gas flow meters, which calibrate a broad range:

- of flow rates from 10 l/h to 3,000 m3/h

- and of viscosities from 0.5 to 1000 cSt

All in compliance with international standards as OIML, API, and ISO and with our customers’ specific requirements.

The Faure Herman flow laboratory can ensure calibration over a dynamic Reynolds Number range of 30 to 3 800 000 and viscosities to 1000 cSt.

The flowmeter calibration is performed by highly trained staff and the process is ISO9001 certified which ensures high quality management and controlling of the procedure.

The flow Laboratory is COFRAC/ILAC certified.

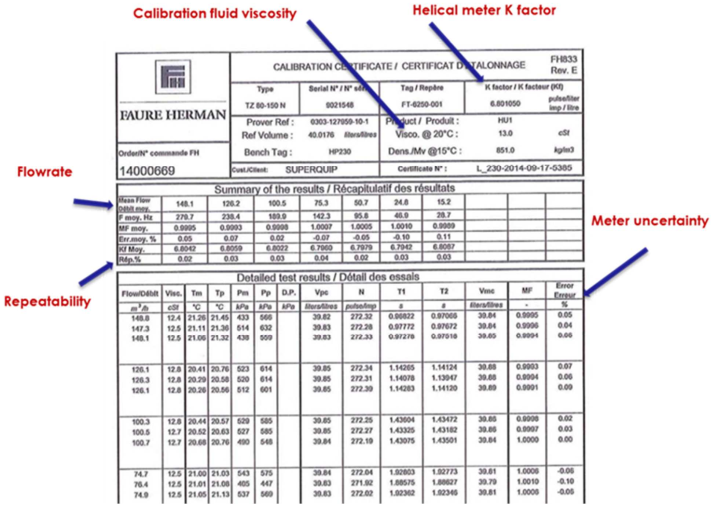

Calibration and traceability

The Faure Herman calibration station in La Ferté Bernard (France) has been accredited as a calibration laboratory for liquid flow measurement by the French Accreditation Committee (COFRAC).

Faure Herman can provide COFRAC calibration certificates in the accredited area of dynamic volume measurement.

These certificates are the only contractual documents to guarantee the uncertainty range.

Working with an ISO/IEC 17025 flow focused metrology laboratory is a guarantee of Quality.

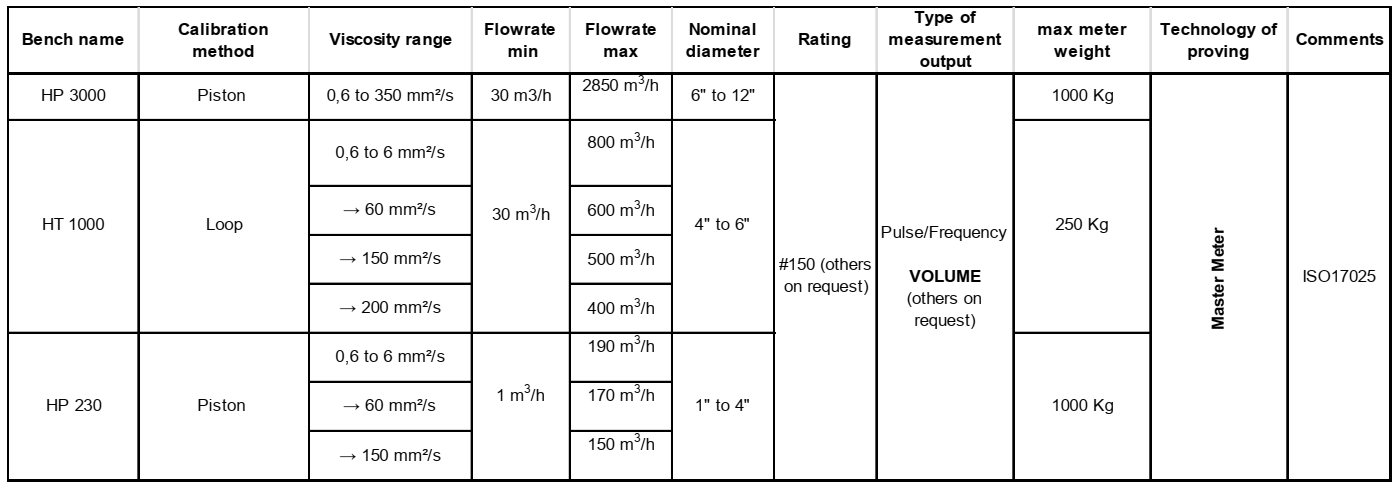

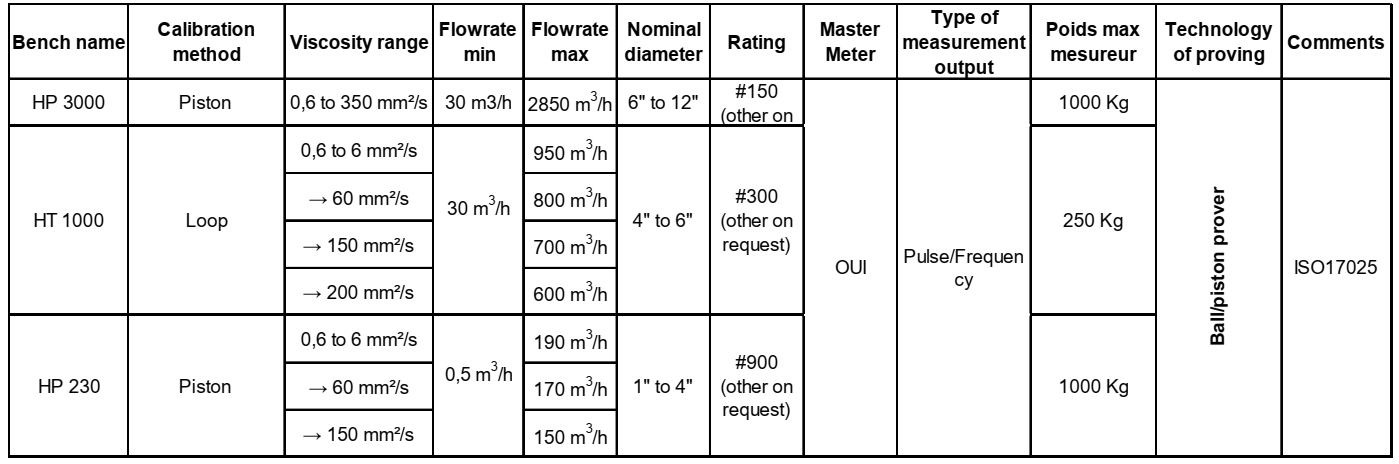

II. FAURE HERMAN TESTING FACILITIES

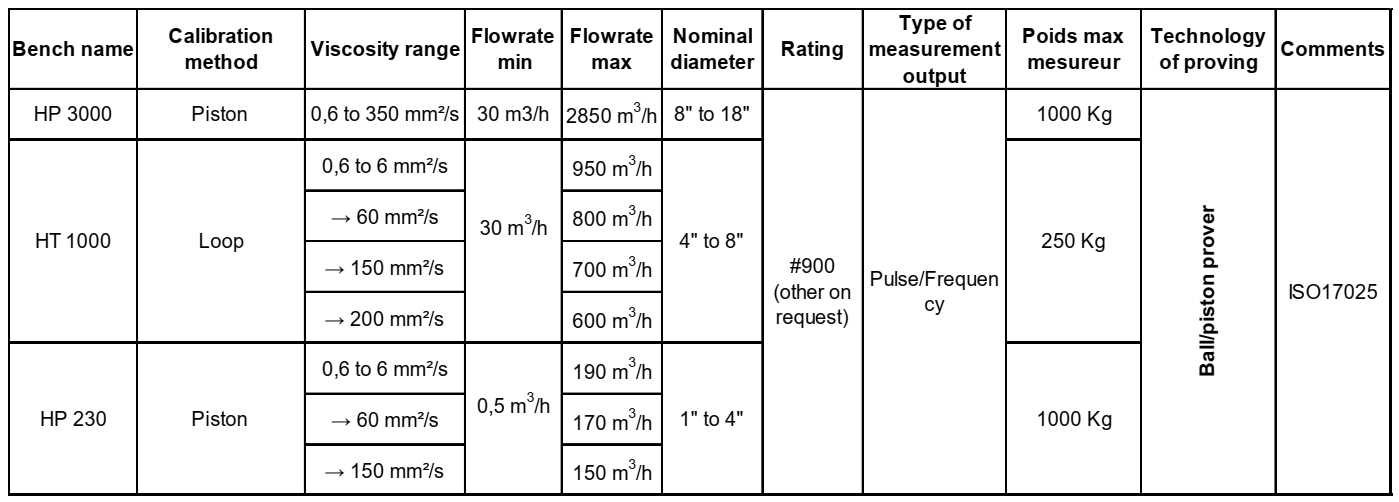

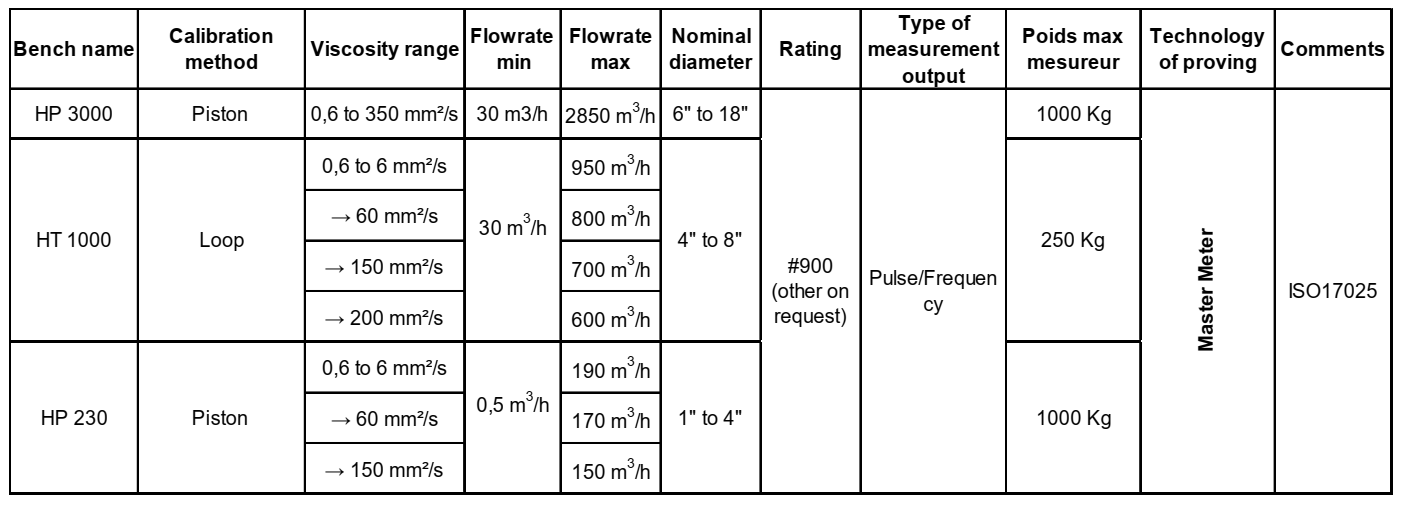

HT 1000 Facility

1.0m3 peco unidirectional

Ball Prover

Meter size 4″ to 8″

Capacity:

Up to 8″

Up to 1000m3/h

Up to 350 cST

Master Meter ability

COFRAC/ILAC Certified

HT 3000 Facility

0.4m3 Brooks Piston Prover

Meter size 8″ to 18″

Capacity:

Up to 18″

Up to 2900 m3/h

Master Meter ability

COFRAC/ILAC Certified

HT 230 Facility

40 litres Daniel Piston Prover

Meter size 1″ to 4″

Capacity:

Up to 4″

Up to 230 m3/h

Master Meter ability

COFRAC/ILAC Certified

III. FACTORY CALIBRATION MAPPING

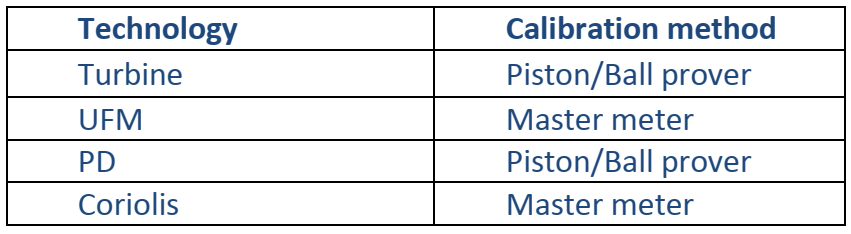

Type of Proving vs. Type of Meter

Faure Herman is able to propose calibration of different types of technology as per the following calibration process mapping:

Liquid Test facilities

Turbine Flowmeter

Ultrasonic Flowmeter

Coriolis Flowmeter

Pressure Differential (PD) Flowmeter

Please contact us for more information and quotation.